Conformal Coating

Features:

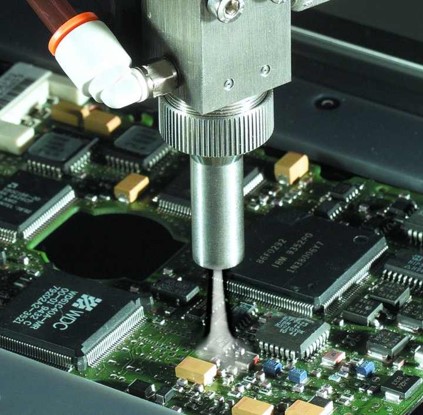

Chemtronics Konform Conformal Coating is used for spray, dip tank, and brush applications. They’re engineered for applications in aerospace, marine manufacturing, electrical equipment, instrumentation, and data communication. They protect printed circuit boards, components and flex circuitry from damage. These coatings provide excellent electrical insulation properties that withstand hot and cold operating environments, thermal shock, mold, and fungus.

Konform coatings come in 2 resin categories:

Acrylic Resin (AR) – Provides fair elasticity and general protection. Recognized for their high dielectric strength, abrasion resistance and ease of removal.

Silicone Resin (SR) – Provides excellent protection in a very wide temperature range, good chemical resistance, salt spray resistance and are very flexible. Removal can be challenging, requiring specialized solvents and long soak time.

Konform SR-X Silicone Conformal Coating

Konform SR-X is a one-part, clear conformal coating with moisture, corrosion and abrasion resistance. It was developed to be the best alternative for Dow Corning conformal coating 1-2577 & 1-2620.

This high-gloss transparent conformal coating provides ideal protection for both rigid and flexible printed circuit boards. Cured coatings are hydrolytically stable and retain their physical electrical properties after high temperature and humidity exposure.

APPLICATIONS:

Extends component life by protecting against adverse environments Resists moisture, salt, fungus, corrosive vapors, and severe environments Designed to provide effective insulation against electrical shorts and harsh environments

Features:

- Engineered for applications where flexibility and high temperature resistance are required

- Exceptional dirt, dust, and soil repellency — surfaces remain clean longer

- Superior transparency

- Superior corrosion resistance

- Low VOC

- Low toxicity – HAPs free

- Silicone coating stable from -76°F/-60°C to 392°F/200°C

- High dielectric strength of 720 volts/mil

- Easily removed with Electro-Wash® Two Step or CircuitWorks® Conformal -Coating Remover Pen

- Contains a UV indicator for quality control inspection

- RoHS Compliant

Konform AR Acrylic Conformal Coating

Konform AR is ideal for providing insulation against high-voltage arcing and corona shorts. This extremely effective acrylic conformal coating provides a hard, durable protective barrier against humidity, salt, corrosive vapors and fungus for printed circuit board and electronic assemblies.

Features:

- Acrylic coating working temperature from -75°F/-59°C to 279°F/137°C

- High dielectric strength of 8300 volts/mil

- Passes the laboratory tests of MIL-I-46058C. However, it is not qualified on QPL-46058.

- Compliant to IPC-CC-830A

- RoHS Compliant

- Provides excellent acid resistance

- Will not discolor over time under normal use

- Easily repairable

- Contains a UV indicator for thorough Quality Control inspection

- UL Recognized, File E76307

Konform® SR Silicone Conformal Coating

Konform SR provides maximum flexibility for extreme temperatures. This transparent conformal coating provides ideal protection for both rigid and flexible printed circuit boards. Cured coatings are hydrolytically stable and retain their physical electrical properties after high temperature and humidity exposure. Konform SR will not stress delicate circuit components.

APPLICATIONS:

Extends component life by protecting against adverse environments Good insulation properties, excellent flexibility Resists moisture, salt, fungus, corrosive vapors, and severe environments Engineered to withstand heat generated by electronic circuitry as well as climatic temperatures

Features:

- Engineered for applications where flexibility and high temperature resistance are required

- Silicone coating stable from -85°F/-64°C to 390°F/199°C

- High dielectric strength of 1100 volts/mil

- Easily removed with Electro-Wash® Two Step or CircuitWorks® Conformal Coating Remover Pen

- Passes the laboratory tests of MIL-I-46058C. However, it is not qualified on QPL-46058.

- Compliant to IPC-CC-830A

- RoHS Compliant

- UL Recognized, File E76307

- UL 94 V-0

- Contains a UV indicator for Quality Control inspection using medium intensity light at 265-335 nm